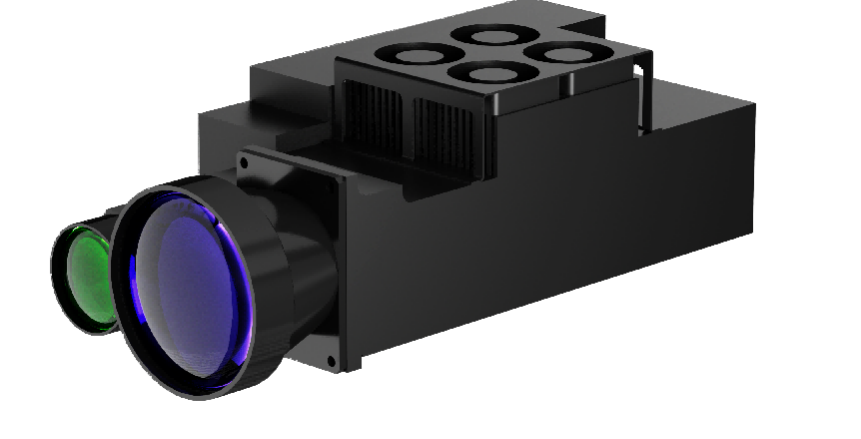

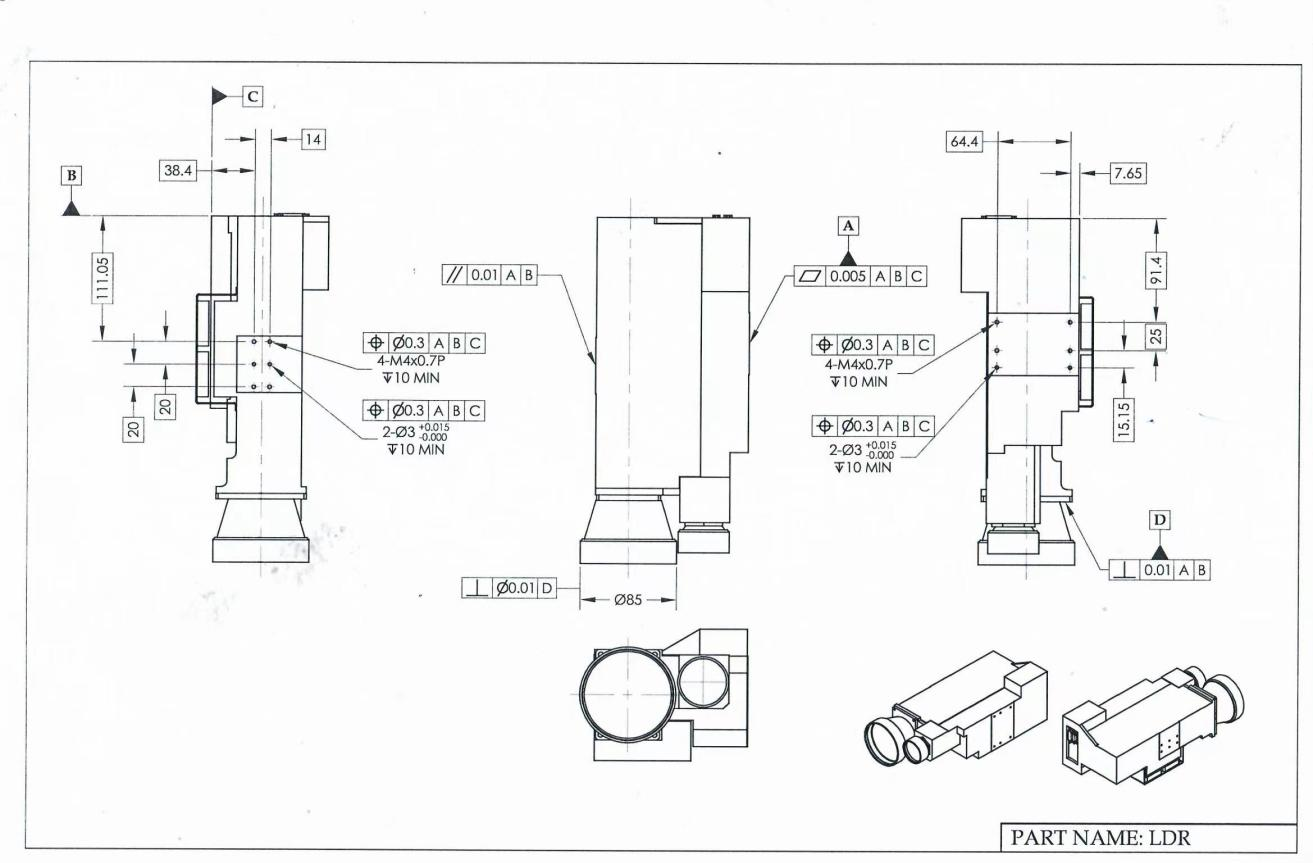

160mJ Laser Target Designator

TECHNICAL SPECIFICATIONS

|

MAIN INDICATORS |

|||||

|

Working wavelength |

1064nm |

||||

|

Laser irradiation energy |

85mJ and 160mJ two gears can be switched |

||||

|

Light delay |

304µs±1µs |

||||

|

Laser beam dispersion Angle |

≤0.2mrad |

||||

|

Irradiation frequency |

8 ~ 21Hz |

||||

|

Ranging frequency |

10Hz |

||||

|

Laser pulse width |

10ns ~15ns |

||||

|

Power stability |

≤±8% |

||||

|

Ranging range |

0.2m ~ 20km (target size 10 m x10 m x8 m, visibility 30km) |

||||

|

Ranging error |

no more than 5 meters |

||||

|

Target selection |

first/second/end |

||||

|

Accurate measurement rate |

≥ 98% |

||||

|

Startup time |

1min (optional) |

||||

|

Working time (suggested) |

Ranging mode |

Laser continuously working for 5min, rest for 4min, 10 consecutive cycles |

|||

|

Irradiation mode |

Irradiation time 120s, rest 60s, continuous 5 cycles |

||||

|

Full set weight |

< 3.3kg |

||||

|

TEMPERATURE |

|||||

|

Operating temperature |

-40℃ ~ +55℃ |

||||

|

Storage temperature |

-40℃ ~ +70℃ |

||||

|

HUMID HEAT |

|||||

|

Relative humidity |

Relative humidity |

||||

|

Temperature |

+25°C±2°C |

||||

|

Storage time |

72h |

||||

|

VIBRATION |

|||||

|

Vibration spectrum shape (grms=6.06) |

20Hz to 80Hz |

+3dB/oct |

|||

|

80Hz to 350Hz |

G2/0.04 Hz |

||||

|

350Hz to 2000Hz |

-3dB/oct |

||||

|

Vibration direction and time |

Vibrate in one direction for at least 10min |

||||

|

Control point |

Should be selected in the fixture or shaking table surface near the maximum stiffness of the product, large equipment can use multi-point average control |

||||

|

Monitoring point |

The monitoring point should be selected in the key part of the product under test, so that the root mean square acceleration response does not exceed the maximum allowable design (grms=6.06) |

||||

|

Installation requirements |

The specimen is rigidly connected to the shaking table, and the product with shock absorber should remove the shock absorber for test |

||||

|

Performance check |

Power-on test during vibration, all performance indicators should meet the technical requirements specified in the design document.In case of failure, it is allowed to repair.When the acceptance test is carried out after repair, the spectrum value should be reduced to 0.01g2/Hz, grms=3.03, and the specimen should be vibrated in the direction most afraid of vibration for 10min |

||||

|

TEMPERATURE RANGE |

|||||

|

Power-on test |

-35±3℃ ~ +52±2℃ |

||||

|

RATE OF TEMPERATURE CHANGE |

|||||

|

Temperature rise |

10℃/min |

||||

|

Cooling |

10℃/min |

||||

|

Cycle times |

10 times, should ensure that the last 2 cycles without fault, if the fault occurs in the last 2 cycles, after repair, need to make up 2 trouble-free cycles |

||||

|

Cycle time |

One cycle time is 4h, one cycle includes temperature rise → temperature stay → cooling → temperature stay → temperature rise |

||||

|

High and low temperature residence time |

The residence time depends on the heat capacity of the specimen. Based on the principle of product thermal or cold permeability, the internal temperature of the specimen is maintained for 5min after reaching stability |

||||

|

The requirements of the product under test |

General temperature cycle test with the whole machine, should be as far as possible to open the cover |

||||

|

Check and repair |

Power test equipment, in each temperature cycle, after the test to confirm that the equipment is fault, can carry out the next temperature cycle |

||||

|

Drenching requirements

|

Drenching is carried out with the whole equipment |

||||

|

SPORTS CAR |

|||||

|

Sports car |

Sports cars go with the whole device |

||||

|

If the product does not do road transport test, you can use the simulation transport table for indoor transport simulation test, that is, sinusoidal cyclic vibration test for product identification |

|||||

|

The requirements of the simulated transport table test are as follows |

|||||

|

Test conditions |

Frequency |

5Hz ~ 200Hz |

|||

|

Amplitude |

5Hz ~ 7Hz |

||||

|

Amplitude 12mm ~ 8mm |

|||||

|

7Hz ~ 200Hz equal acceleration 1.5g |

|||||

|

Vibration test condition allowable deviation is the same as broadband random vibration test |

|||||

|

Direction |

vertical axle direction and side |

||||

|

Orientation |

vertical and lateral to the axle |

||||

|

Cycle time |

log-scan 5Hz ~ 200Hz ~ 5Hz, 12min per cycle;When the resonant frequency of the specimen is measured below 5Hz, the test frequency can be extended to 2Hz, 2Hz ~ 200Hz ~ 2Hz scanning, scanning time should be 15min.The vibration time in each direction is 90min |

||||

|

After transportation test, check whether there is damage and structural loosening phenomenon, carry out technical index inspection, should meet the design requirements.

|

|||||

|

KEY PERFORMANCE INDICATORS |

|||||

|

Power supply and power consumption |

Power supply range |

20V ~ 33V, DC |

|||

|

Power consumption |

peak power is not more than 400W, standby power is not more than 60W (limit temperature). 1.5.2 Reliability |

||||

|

Reliability |

MTBF is not less than 4000h |

||||

|

Security |

Set up a warning device for the laser to work |

||||

|

The exit of the laser transmitter is provided with obvious warning signs |

|||||

|

The equipment is well grounded |

|||||

|

Maintainability |

All major functional parts and equipment are set up fault indication and normal working indication |

||||

|

The average repair time MTTR is not more than 20min |

|||||

|

Electromagnetic compatibility requirements |

In the system boot operation process, the equipment can be compatible with other equipment in the system, normal work |

||||